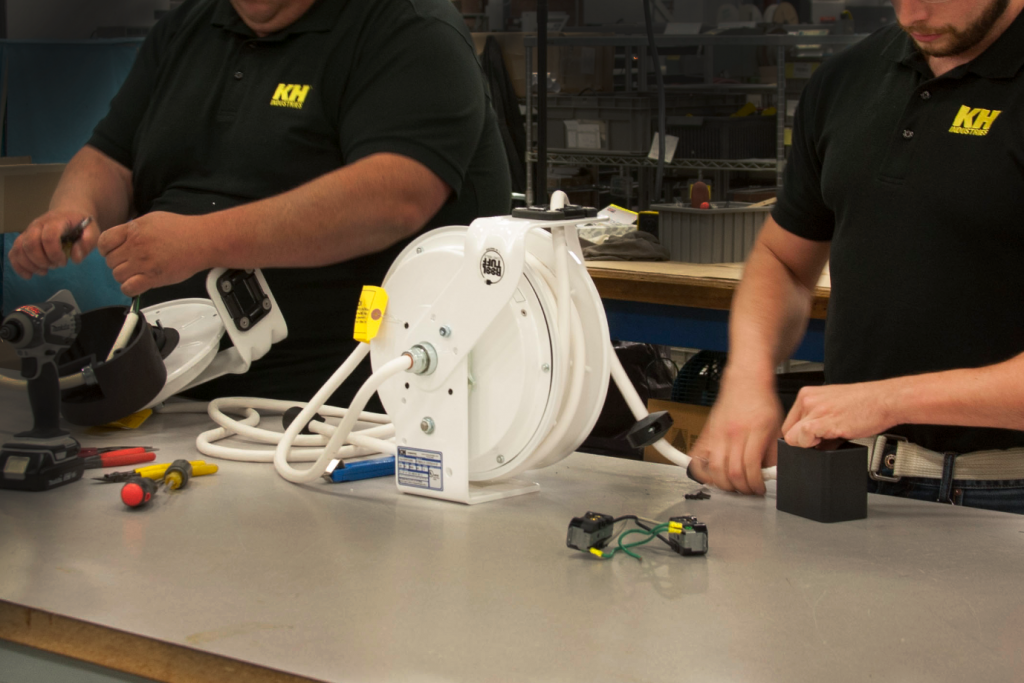

Industrial Power Cord Reels for OEMs: How KH Industries Supports Equipment Builders With In-House Expertise

Last updated on February 9th, 2026 at 04:03 pm

OEMs that integrate industrial power cord reels into large equipment — whether for manufacturing machinery, mobile utility equipment, shipyards, transportation assets, or material processing systems — often find that basic commodity reels can’t meet performance, environment, or footprint requirements.

What OEMs need is a partner with a deep product line of heavy-duty power cord reels and the engineering depth to align the proper configuration with the application — not a reseller or a slow, one-off design shop.

That is precisely the space KH Industries occupies.

Why OEMs Choose KH for Power Cord Reel Integration

Most OEM applications can be solved using KH’s standard industrial power cord reels with configurable attributes, including:

- cable length, gauge, jacket, and temperature rating

- amperage and voltage requirements for continuous duty

- NEMA 2 / 4 / 4X enclosures for environmental exposure

- slip ring selection matched to load and duty cycle

- mounting geometry and cable exit orientation

- connector types, strain relief, and interface selections

- OEM color/identification as needed for equipment integration

These are standard or made-to-order configurations, not engineered one-offs — which protects lead time, cost, supply chain repeatability, and UL/ETL compliance for OEM programs.

When a “Custom” Power Cord Reel is Actually Required

Only a small percentage of OEM cases call for a truly engineered power cord reel — typically when:

- the envelope or mounting cannot be solved with standard geometry

- hazardous/classified certification exceeds standard ratings

- electrical integration requires unique interlocks or logic

- retrofit conditions eliminate all standard fit envelopes

- safety/compliance constraints mandate net-new design

In those cases, KH provides true custom engineering — but only when no standard or configurable solution exists.

KH vs Commodity Reel Suppliers for OEM Use

Commodity reel vendors optimize for volume — not for heavy-duty OEM duty cycles, mounting constraints, or integration risk.

KH Industries supports OEMs with:

- U.S. manufacturing for repeatable production

- direct engineer access (not distributor layers)

- heavy-industrial design intent from day one

- short path to a validated, production-ready spec

That materially reduces OEM risk, downtime, and rework during integration.

OEM Engagement Process for Power Cord Reels

- Define Application Load & Environment

Voltage, current, duty cycle, chemicals, moisture, vibration, temperature - Map to Standard / Configurable KH Platforms First

Faster approval, repeatability, and controlled cost - Escalate to Engineered-to-Spec Only When Required

Reserved for true edge-cases, not by default - Validate, Document, and Release for OEM Production

Compliance, repeatability, lifecycle support - Support After Release

Rebuildable assemblies, parts availability, U.S. service

OEM Buyer FAQ: Industrial Power Cord Reels

Q1 — Can industrial power cord reels be configured to our electrical requirements?

Yes. Most applications can be met using configurable standard options — including cable gauge, length, temperature rating, amperage, voltage, and connector style — without needing a fully custom design.

Q2 — What enclosure or protection ratings are available for harsh environments?

Industrial power cord reels are available in NEMA 2/4/4X configurations. They can be built with corrosion-resistant hardware, sealed bearings, powder-coated housings, and ingress protection suitable for dust, moisture, washdown, and chemical environments.

Q3 — What information does KH need to recommend the correct reel?

OEMs should provide voltage/current, duty cycle, environmental conditions (oil, dust, vibration, temperature), mechanical envelope/mounting, and any UL/NEC/ETL requirements. With that, KH can map to standard or made-to-order options.

Q4 — Do we always need a custom-engineered reel for OEM integration?

No. Most OEM use cases are solved with KH’s standard industrial catalog by selecting the correct configuration. Custom engineering is reserved for rare instances in which standard geometry or ratings cannot meet the application requirements.

Q5 — Can KH support repeat production for long-run OEM programs?

Yes. KH manufactures in the U.S. with controlled processes for consistency across production cycles, and provides documentation, BOM stability, and rebuild/repair support for lifecycle continuity.

Q6 — How do industrial cord reels impact safety and compliance?

Correctly specified reels help prevent insulation breakdown, cable fatigue, overheating, and improper routing — and can be selected or built to meet UL/ETL, NEC, and hazardous-location requirements where applicable.

Q7 — What are typical lead times for OEM power cord reels?

Standard and configurable industrial reels are available on significantly shorter lead times than fully custom builds. Lead time depends on configuration complexity and certification requirements.

Bottom Line for OEM Teams

Choosing KH for industrial power cord reels means you get:

- broad standard platform that already fits most OEM use cases

- application-level engineering support when needed

- custom work only when the application actually demands it

That combination gives OEMs speed, reliability, and lifecycle certainty — without committing to one-off engineering unless it is the only viable option.

Get In Touch

Talk to KH Industries about industrial power cord reels for OEM integration.

Whether you need a configurable reel from KH’s standard platform or an engineered solution for a non-standard environment, the KH engineering team will map the fastest and most reliable path to a correct build.